Hot Topics

Vol. 61, No. 7, July (2012)

|

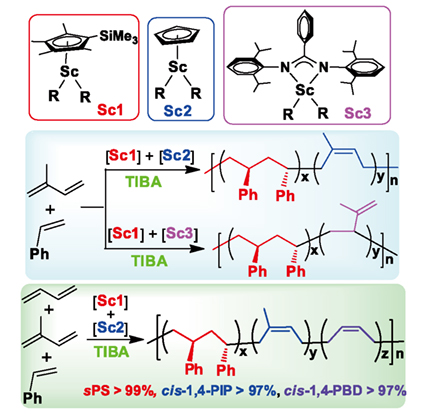

Chain-Shuttling Copolymerization of Styrene and 1,3-Conjugated Dienes by Rare-Earth Catalysts

Zhaomin HOU RIKEN Advanced Science Institute, Organometallic Chemistry Laboratory |

||

|

|

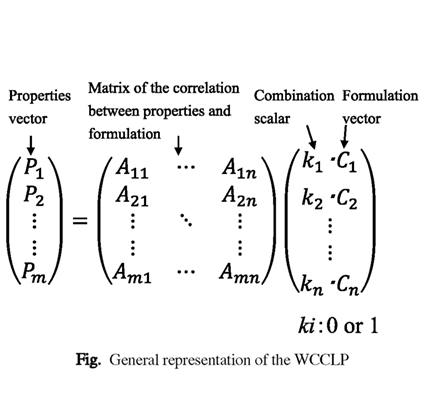

Intelligent Material Design System based on Weak Conditioned Linear Programming

Teiichi INADA Hitachi Chemical Co., Ltd., Tsukuba Research Laboratory |

||

|

|

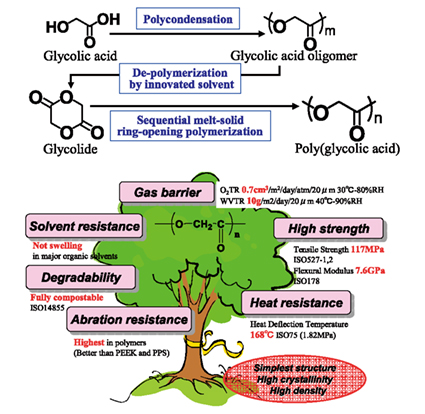

Industrial Production Technology for High Molecular Weight Polyglycolic Acid

Hiroyuki SATO PGA Research Laboratories, Kureha Corporation |

||

|